Description

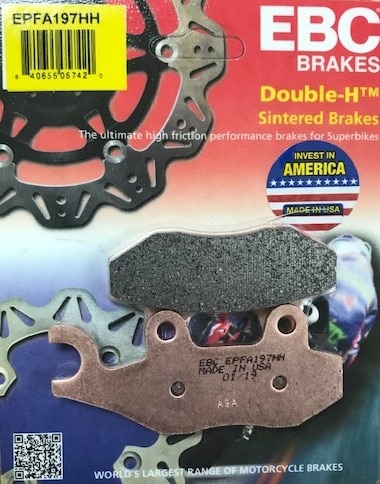

The Racing EBC Brake Pads EPFA197HH has more stability, faster bed-in and more bite, these Racing Brake Pads are longer lasting ultra high friction sintered road race brake pads are the only choice for road racing. This compound is the result of an amazing breakthrough in the EBC Brake Pads research and development facility in Ohio, USA.

This new compound is even better than the GPFA compound which it replaces. For use only in closed circuit. Use on the street is inadvisable and even dangerous due to the high friction levels these pads deliver.

The high friction levels make this pad perfect for track conditions with race tires or slick tires on asphalt surfaces, they are not suitable for use on the street with street tires. Street use is illegal due to the material not having ECE R90 type approval and not being TÜV tested with a German ABE.

After 35 years as the worlds number one brand, EBC Brakes has accumulated massive experience on how to guide its customers to enjoy their brake products safely.

Bedding in new motorcycle pads and rotors is an extremely important process – please follow these guidelines:

Fitting New Disc Pads To Used Brake Discs/Rotors

First of all, there are two different types of brake pad on the world markets which are sintered copper alloy or organic types. The sintered types are of course much harder and take 3-5 times longer to bed in GEOMETRICALLY to any hollow areas or ridges on a worn brake rotor. Organic pads being slightly softer bed in more quickly but also suffer from what is known as “green fade”. Green fade is explained as a heat curing of the brake material which happens over the first heavy heat cycles.

To bed in sintered pads, drive the vehicle carefully allowing extra braking distance for the first 300 miles. Please be aware that brake performance during the bed in period may be significantly less than you have been accustomed to. What you are looking for is to see a 90%+ surface area contact between the pad and the disc or rotor before optimum braking will be achieved.

Once your pads are 90% surface area bedded after the 300-400 miles, on a safe road, use the brakes 10 times in succession stopping your motorcycle from 60mph to 20mph to get the brakes deliberately hot. This is particularly important with the organic versions (aramid fibre types, carbon based pad types and semi-metallic pad types). After this process, the pads should settle down and normal riding and brake performance can be safely achieved.

Fitting New Disc Pads With New Brake Discs/Rotors

Although the brake disc/rotor surface will be perfectly flat when using a new rotor, it is still extremely important to “condition” the brake discs and match them up to your pads by driving gently for 200-300 miles. After this period, perform the heat bedding of organic pads as above in blue text.

Always remember not to contaminate your brake pads with any fluids or greases (even brake fluid) during the install process.

If you experience any vibration or serious loss of brake during this process, contact a professional motorcycle dealer for assistance.

Bedding In New Brakes for Trackday or Race Use

If you are using your motorcycle for a trackday or race event, bedding in the new pads is even more important. 99% of racers use sintered pads for trackday and race events because they do not require chemical bedding as in blue above, but these pads still need to be matched to the rotor and therefore a bedding in process of 2-3 laps gentle brake use gradually increasing brake pressure and load after that has been completed is advisable.

EBC Brakes make some excellent trackday pads such as their EPFA range or the full race GPFAX range.

EBC Brake Pads EPFA197HH are used by racers around the world

Reviews

There are no reviews yet.