Service alerts

International Postal service disruptions

International Mail Service Suspensions

Updated: Oct. 1, 2021

The Postal Service™ is temporarily suspending international mail acceptance for certain destinations due to impacts related to the COVID-19 pandemic and other unrelated service disruptions.

Suspension Due to Unavailability of Transportation

| Afghanistan | Guadeloupe | New Zealand** | Tajikistan |

| Australia* | Laos | Reunion (Bourbon) | Timor-Leste |

| Bhutan | Libya | Saint Pierre and Miquelon (Miquelon) | Turkmenistan |

| Brunei | Martinique | Samoa | Yemen |

| Cuba | Mayotte | South Sudan | French Guiana |

| Mongolia | Syria |

Customers: please refrain from mailing items addressed to the countries listed here, until further notice.

These service disruptions affect Priority Mail Express International® (PMEI), Priority Mail International® (PMI), First-Class Mail International® (FCMI), First-Class Package International Service® (FCPIS®), International Priority Airmail® (IPA®), International Surface Air Lift® (ISAL®), and M-Bag® items.

*Australia’s service disruption affects Priority Mail International® (PMI), First-Class Package InternationalService® (FCPIS®), Commercial ePacket (CeP), International Priority Airmail® (IPA®) packets, InternationalPriority Airmail® (IPA®) M-Bags, International Surface Air Lift® (ISAL®) packets, International Surface Air Lift®(ISAL®) M-Bags, and Airmail M-Bags.

**New Zealand’s service disruption affects Priority Mail International® (PMI), First-Class Package International Service® (FCPIS®), Commercial ePacket (CeP), International Priority Airmail® (IPA®) packets, International Priority Airmail® (IPA®) M-Bags, International Surface Air Lift® (ISAL®) packets, International Surface Air Lift® (ISAL®) M-Bags, and Airmail M-Bags.

Unless otherwise noted, service suspensions to a particular country do not affect the delivery of military and diplomatic mail.

Spears Racing will completely inspect all of the working components of the engine:

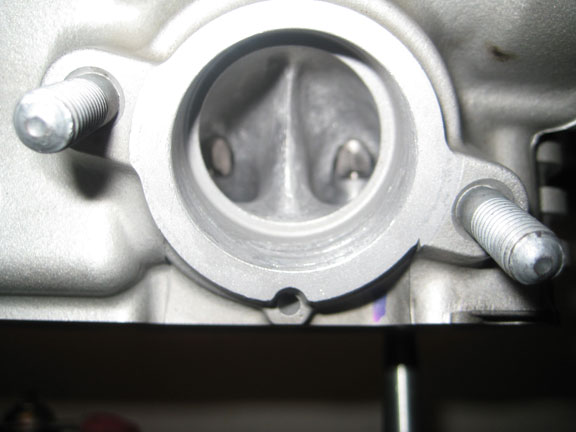

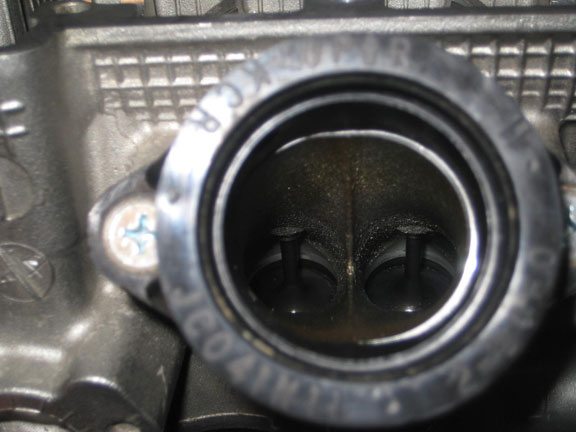

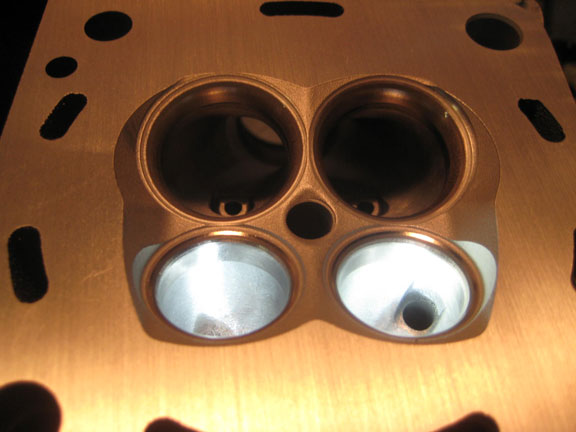

The top end will be torn down and careful measurement of the piston to head (squish) must be taken to avoid collision of the moving parts and the cylinder heads will be completely inspected. Increasing the compression ratio of an engine by machining the gasket surface of the cylinder head is where most of an engine’s power increase comes from.

Compression ratios can also be increased by machining the engine cylinder deck or changing the thickness of the head gasket or a combination of the aforementioned, Spears Racing has designed several different pistons for all of the lightweight engines that often are a great fit.

Spears Racing offers several types of head work to match your needs. First there is a STANDARD valve job, which machines the valves and seat area of the head exactly to the manufacturers required specifications. Second there is the competitive valve job (Referred to a SUPERSPORT Style) the valve faces and stems are machined, and the intake valves are given a special double cut. The exhaust seats are given a three angle cut. The intake seats receive a blended four angle cut or full radius cut depending on the application. Finally all valves are hand lapped and checked for correct sealing. All of the seat work is done on our state-of-the-art valve machine. Once the cylinder head has been machined and thoroughly cleaned, it is time for reassembly. Careful assembly of the cylinder head involves checking valve spring height and pressures as well as setting the valve lash for proper clearance.

Spears Racing will completely inspect all of the working components of the engine:

The top end will be torn down and careful measurement of the piston to head (squish) must be taken to avoid collision of the moving parts and the cylinder heads will be completely inspected. Increasing the compression ratio of an engine by machining the gasket surface of the cylinder head is where most of an engine’s power increase comes from.

Compression ratios can also be increased by machining the engine cylinder deck or changing the thickness of the head gasket or a combination of the aforementioned, Spears Racing has designed several different pistons for all of the lightweight engines that often are a great fit.

Spears Racing offers several types of head work to match your needs. First there is a STANDARD valve job, which machines the valves and seat area of the head exactly to the manufacturers required specifications. Second there is the competitive valve job (Referred to a SUPERSPORT Style) the valve faces and stems are machined, and the intake valves are given a special double cut. The exhaust seats are given a three angle cut. The intake seats receive a blended four angle cut or full radius cut depending on the application. Finally all valves are hand lapped and checked for correct sealing. All of the seat work is done on our state-of-the-art valve machine. Once the cylinder head has been machined and thoroughly cleaned, it is time for reassembly. Careful assembly of the cylinder head involves checking valve spring height and pressures as well as setting the valve lash for proper clearance.

For those not wishing to radically modify the ports, port irregularities and casting lumps (called flashings) are removed. The critical area of valve-seat-to-port is blended and the junction of the carburetor-adapter to-manifold is also matched and blended, the complete port and combustion chamber reshaping, the area is shaped and contoured to maximum flow and while maintaining flow velocity for power increases throughout the RPM range.

For those not wishing to radically modify the ports, port irregularities and casting lumps (called flashings) are removed. The critical area of valve-seat-to-port is blended and the junction of the carburetor-adapter to-manifold is also matched and blended, the complete port and combustion chamber reshaping, the area is shaped and contoured to maximum flow and while maintaining flow velocity for power increases throughout the RPM range.

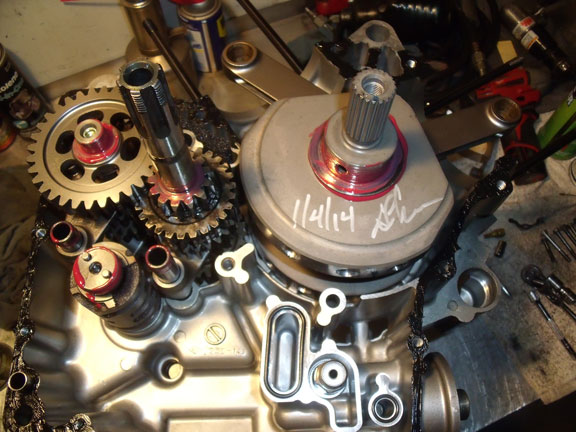

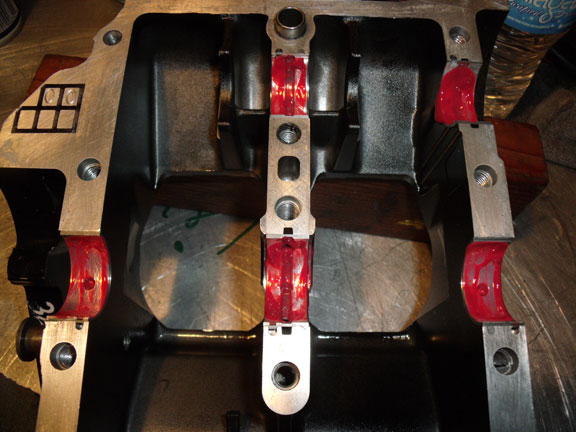

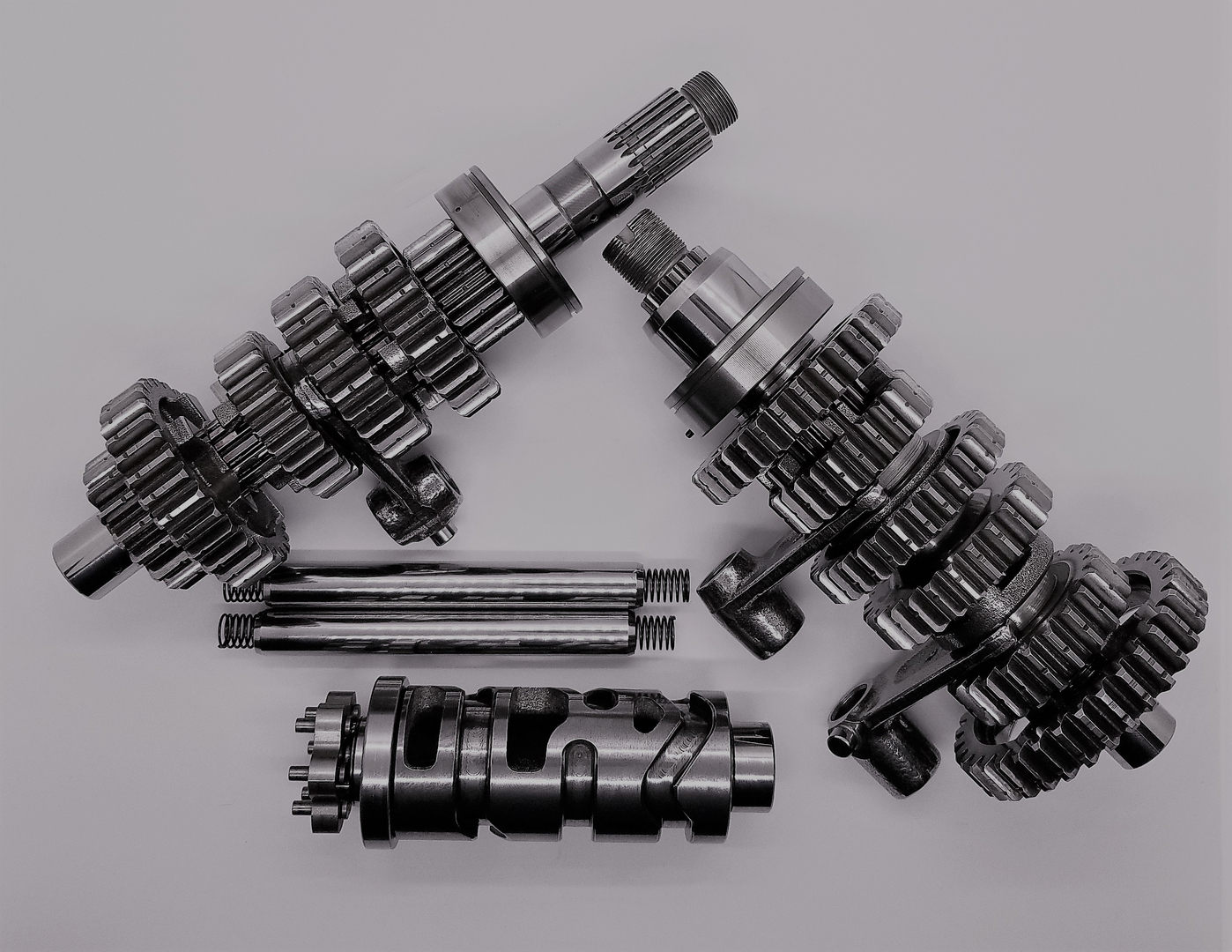

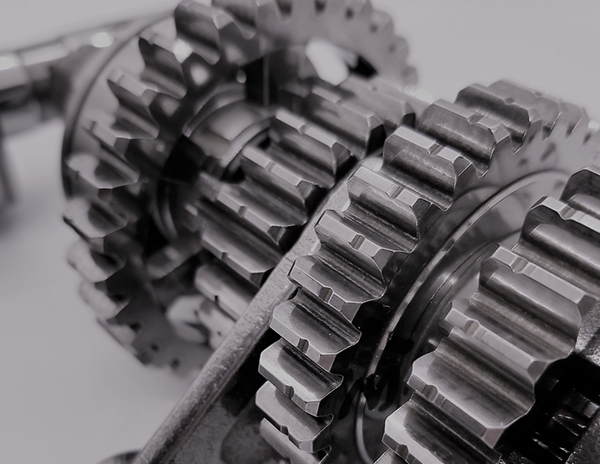

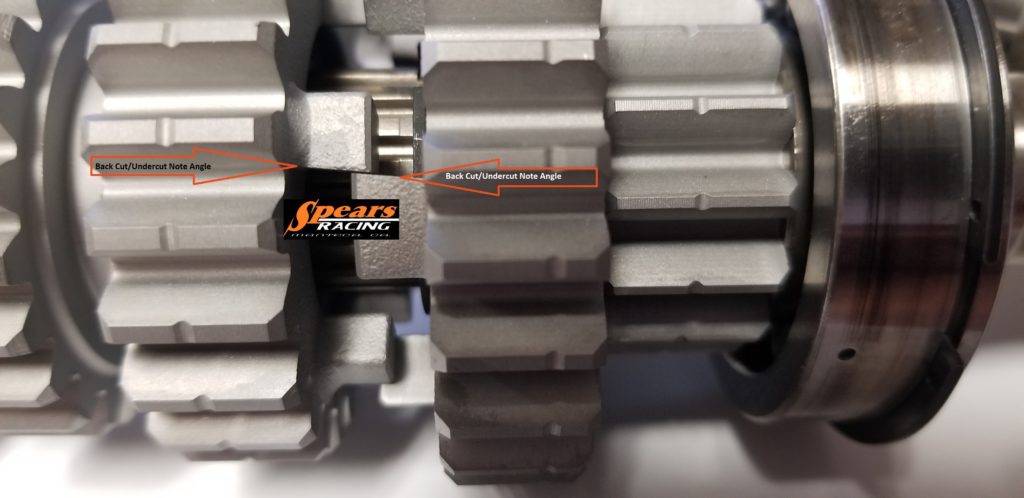

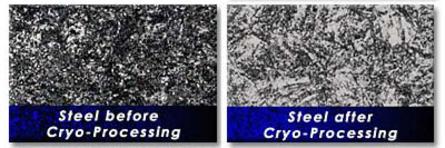

The Lower end is disassembled after the cylinder head has been removed from the engine. While the factories do a fine job on assembly, they leave a few small details to be taken care of. Oil clearances can be carefully set at a higher clearance and checked with Plastic gauge, oil pumps can be modified and things like ceramic transmission bearings and Cyroing and Micro-Polishing can be done to “free up” inertial and frictional power losses.

Other modifications on the bottom end can include bead blasting piston crowns, checking piston to cylinder wall clearances and changing/setting if necessary, oil pump and oil pressure relief valve modification for changing pressure output and transmission modifications. The cylinders will be installed and the proper deck height will be obtained to give the best reliable power and torque. Next are the cylinder head(s) – a process that only Spears does. The heads are bolted to the cylinders and are CC’d to find out the current compression ratio. After this is completed, the heads are ready for there finial assembly to the cylinders. The transmission will be clearanced in the cases and new transmission carrier bearings will be installed if needed (upgrade to Ceramic). The crankshaft will be magnafluxed to ensure that it has no cracks at the time of installation and this too will be clearanced in the cases for the correct clearances. The connecting rods will also be clearanced at this time. If an upgrade is wanted, we suggest the Carrillo connecting rods. The cases will be prepped with new main crankshaft bearings as well. After final inspection, the Spears crank case defuser (depending on the engine type) and the cases will be closed up. While the cylinder head is disassembled and being machined, it is recommended to have a valve job performed to give the valve seat better flow and sealing characteristics.

The Lower end is disassembled after the cylinder head has been removed from the engine. While the factories do a fine job on assembly, they leave a few small details to be taken care of. Oil clearances can be carefully set at a higher clearance and checked with Plastic gauge, oil pumps can be modified and things like ceramic transmission bearings and Cyroing and Micro-Polishing can be done to “free up” inertial and frictional power losses.

Other modifications on the bottom end can include bead blasting piston crowns, checking piston to cylinder wall clearances and changing/setting if necessary, oil pump and oil pressure relief valve modification for changing pressure output and transmission modifications. The cylinders will be installed and the proper deck height will be obtained to give the best reliable power and torque. Next are the cylinder head(s) – a process that only Spears does. The heads are bolted to the cylinders and are CC’d to find out the current compression ratio. After this is completed, the heads are ready for there finial assembly to the cylinders. The transmission will be clearanced in the cases and new transmission carrier bearings will be installed if needed (upgrade to Ceramic). The crankshaft will be magnafluxed to ensure that it has no cracks at the time of installation and this too will be clearanced in the cases for the correct clearances. The connecting rods will also be clearanced at this time. If an upgrade is wanted, we suggest the Carrillo connecting rods. The cases will be prepped with new main crankshaft bearings as well. After final inspection, the Spears crank case defuser (depending on the engine type) and the cases will be closed up. While the cylinder head is disassembled and being machined, it is recommended to have a valve job performed to give the valve seat better flow and sealing characteristics.